What is Robot?

A robot is a machine that gathers information about its environment (senses) and uses that information (thinks) to follow instructions to do work (acts).Many things in your home include sensors and/or programmable computer chips that control their operation -- for example your programmable VCR, remote car locking systems and furnace thermostat which responds to room temperature and may be programmed to turn the heat down at night and up in the morning. However, robotic engineers would probably not say your VCR or thermostat is a robot. Likewise, robots are doing more and more.Today's robots are incorporating multiple sensors and are able to use this information to behave autonomously -- making decisions for themselves based on information that they receive.There is endless variety in the size, shape and jobs of robots. Some robots are used day after day in factories, while others are highly experimental and use artificial intelligence to behave more and more like living creatures, able to act independently in changing environments. Robots are being designed to perform precision surgery, explore space, the ocean, other dangerous areas.

THe Short History of Robots:

Robot Timeline

~270BC an ancient Greek engineer named Ctesibus made organs and water clocks with movable figures.

1818 - Mary Shelley wrote "Frankenstein" which was about a frightening artificial lifeform created by Dr. Frankenstein.

1921 - The term "robot" was first used in a play called "R.U.R." or "Rossum's Universal Robots" by the Czech writer Karel Capek. The plot was simple: man makes robot then robot kills man!

1941 - Science fiction writer Isaac Asimov first used the word "robotics" to describe the technology of robots and predicted the rise of a powerful robot industry.

1942 - Asimov wrote "Runaround", a story about robots which contained the "Three Laws of Robotics":A robot may not injure a human, or, through inaction, allow a human being to come to harm.A robot must obey the orders it by human beings except where such orders would conflic with the First Law.A robot must protect its own existence as long as such protection does not conflict withe the First or Second Law.

1948 - "Cybernetics", an influence on artificial intelligence research was published by Norbert Wiener

1956 - George Devol and Joseph Engelberger formed the world's first robot company.

1959 - Computer-assisted manufacturingg was demonstrated at the Servomechanisms Lab at MIT.

1961 - The first industrial robot was online in a General Motors automobile factory in New Jersey. It was called UNIMATE.

1963 - The first artificial robotic arm to be controlled by a computer was designed. The Rancho Arm was designed as a tool for the handicapped and it's six joints gave it the flexibility of a human arm.

1965 - DENDRAL was the first expert system or program designed to execute the accumulated knowledge of subject experts.

1968 - The octopus-like Tentacle Arm was developed by Marvin Minsky.

1969 - The Stanford Arm was the first electrically powered, computer-controlled robot arm.

1970 - Shakey was introduced as the first mobile robot controlled by artificial intellence. It was produced by SRI International.

1974 - A robotic arm (the Silver Arm) that performed small-parts assembly using feedback from touch and pressure sensors was designed.

1979 - The Standford Cart crossed a chair-filled room without human assistance. The cart had a tv camera mounted on a rail which took pictures from multiple angles and relayed them to a computer. The computer analyzed the distance between the cart and the obstacles.

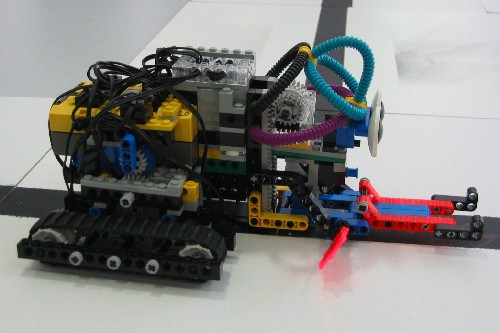

Main Parts of a Robot:

A robot has five main parts:

1. Arm

2. Controller

3. Drive

4. End Effector

5. Sensor

6. Arm

ARM:

The arm of the robot is a significant part of the robotic architecture. It positions the End effector and the sensors that the robot will require. Most arms resemble the human limb-the arm. Some of these arms have many complex parts including fingers, wrists, and elbows. This enables the robot different methods of movement.Seven degrees of freedom are needed for a robot to reach all points in its work envelope. Each direction a joint can go gives an arm one degree of freedom. Simple robots usually have three degrees of freedom-it can move in three ways: up and down, left and right, and forward and backward.To determine what each degree of freedom means and represents:First degree of freedom is called a shoulder pitch. To find your arm's first degree of freedom, point your entire arm straight out in front of you. Move your shoulder up and down. The up and down movement of the shoulder is called the shoulder pitch.Second degree of freedom is called an arm yaw. Point your entire arm straight out in front of you. Move your entire arm from side to side. This side-to-side movement is called the arm yaw.Third degree of freedom is called a shoulder roll. Point your entire arm straight out in front of you. Now, roll your entire arm from the shoulder, as if you were screwing in a light bulb. This rotating movement is called a shoulder roll.Fourth degree of freedom is called elbow pitch. Point your entire arm straight out in front of you. Hold your arm still, and then bend only your elbow. Your elbow can move up and down. This up and down movement of the shoulder is called the elbow pitch.Fifth degree of freedom is called a wrist pitch. Point your entire arm straight out in front of you. Without moving your shoulder or elbow, flex your wrist up and down. This up and down movement of the wrist is called the wrist pitch.Sixth degree of freedom is called a wrist yaw. Point your entire arm straight out in front of you. Without moving your shoulder or elbow, flex your wrist from side to side. The side-to-side movement is called the wrist yaw.Seventh degree of freedom is called the wrist roll. Point your entire arm straight out in front of you. Without moving your shoulder or elbow, rotate your wrist, as if you were turning a doorknob. The rotation of the wrist is called the wrist roll.

Controller:

The controller functions as the "brain" of the robot. It can also network to other systems so that the robot may work together with other robots or machines. Controllers can become very complicated. There are many computer-based controllers on the market and many robot languages, such as Prolong.

End Effector:

The End Effector is the hand connected to the arm. In humans, the End effector is the hand. However, in robots, the End effector can be of many different things. It could range from a being a tweezer, to a blowtorch.

Drive:

The drive is the engine of the robot. It enables mobility and movements between the joints of the arm. It can be powered by air, electricity, and/or water.

Robotic Sensors:

Sensors provide a robot with feedback so that it can "understand" its surroundings-otherwise a robot would be not only blind, but also deaf to its environment.A few common kinds of sensors are listed below.---Cameras - Cameras are inexpensive and usable for many kinds of imaging applications. They enable a robot to process its environment so that it can move freely without bumping into something.---Range finding devices - There are four basic techniques for distance measurement using electromagnetic radiation. They are Doppler methods, interferometry, phase comparison, and pulse timing.---Sonar sensors - These kinds of sensors work by measuring the time it takes for an acoustic pulse to propagate through air or water, reflect from the environment, and finally return to a detector, is proportional to the distance to that object.

Application of Robot:

Robots, whether teleoperated, under supervisory control, or autonomous, have been used in avariety of applications in maintenance and repair. The following subsections describe many of thesesystems, focusing primarily on applications for which working robot prototypes have beendeveloped.

Robot in Nuclear Industry:

In the nuclear industry, teleoperators have been well-utilized in the maintenance role for more than 4 decades. Several features of maintenance make it a good application for teleoperators in this arena.First is the low frequency of the operation, which calls for a general-purpose system capable of doing an array of maintenance tasks. Second, maintenance and repair require high levels of dexterity.Third, the complexity of these tasks may be unpredictable because of the uncertain impact of a failure. For these reasons, the choice for this role is often between a human and a teleoperator.Thus, when the environment is hazardous, a teleoperator is usually the best selection. If humans in protective clothing can perform the same job, the benefits of having teleoperators continuously at the work site need to be weighed against the cost of suiting up and transporting humans to and from the work site. While humans are likely to be able to complete tasks more quickly than teleoperators, using teleoperators can: (1) shorten mean time to repair by reducing the response time to failures, (2)reduce health risks, (3) improve safety, and (4) improve availability by allowing maintenance to take place during operations, instead of halting operations.As an example of the importance of maintenance for nuclear industry robotics, the proceedings of the 1995 American Nuclear Society topical meeting on robotics and remote handling included 124 papers, nearly a quarter of which were devoted to some aspect of maintenance. The 1997 meeting included 150 papers, where more than 40% dealt with some aspect of maintenance. Furthermore, if one considers environmental recovery operations as a form of maintenance, then a much larger proportion of papers at both meetings were maintenance-related.

Robot in Highway building:

In the developed world, highways are a critical component of the transportation network. Thevolume of traffic on the roadways has been steadily increasing for many years as society becomesmore and more mobile. However, the funding to maintain these roadways has not been keeping pacewith the traffic volume. The result is deteriorating roadways that cannot be adequately maintained.Conventional techniques to road repair lead to traffic congestion, delays, and dangers for the workers and the motorists. Robotic solutions to highway maintenance applications are attractive due to their potential for increasing the safety of the highway worker, reducing delays in traffic flow, increasing productivity, reducing labor costs, and increasing quality of the repairs.Application areas to which robotics can be applied in this area include (Ravani and West, 1991):

• highway integrity management (crack sealing, pothole repair)

• highway marking management (pavement marker replacement, paint re-striping)

• highway debris management (litter bag pickup, on road refuse collection, hazardous spillcleanup, snow removal)

• highway signing management (sign and guide marker washing, roadway advisory)

• highway landscaping management (vegetation control, irrigation control)

• highway work zone management (automatic warning system, lightweight movable barriers,automatic cone placement and retrieval)

Robots in Railway Industry:

The railroad industry has recognized the economic benefits of automation, which has lead to thedevelopment of a number of robotic solutions to maintenance and repair applications in the industry.The railway maintenance shops are the most common location of robots, which perform activities such as welding, grinding, cleaning, and painting (Martland, 1987).Another robotic system developed by the railway industry is the RMS-2 rail grinding system(Anonymous, 1986). Developed by Speno Rail Services Co., this system has automated capabilitiesto sense the existing condition of the surface of the rails. Up to 99 patterns are stored thatcorrespond to rail contour patterns. An integrated onboard computer system is used to generateonboard grinder controls for finishing the rail to the appropriate, pre-determined rail contour. TheRMS-2 has 120 stones for grinding spread along the underside of five of the twelve railway cars thatmake up the system. The system is capable of grinding rails at speeds up to 6 miles per hour.

Robots in Underwater Facilities:

Teleoperated robots are widely used to maintain facilities beneath the surface of the ocean, mainly inservice of the offshore oil industry. Specific applications include repairing communications cables, pipelines, well heads, and platforms. Teleoperators have also been deployed to clean marine growth from power plant cooling systems (Edahiro, 1985), to inspect and clean steam generators (Trovato &Ruggieri, 1991), perform underwater construction (Yemington, 1991), and to inspect and repair water conveyance tunnels (Heffron, 1990). While these efforts do not have the visibility of robotics work in industrial, space, or nuclear applications, it is an arena in which robotics and remote control technology are widely used. It is perhaps the most common venue for everyday use of teleoperated robots. One publication lists 63 companies involved in building remotely operated vehicles ormanipulators for sub-sea work and 180 different, commercially available, remotely controlled systems (Gallimore & Madsen, 1994). The remotely operated systems range from towed sensorarrays to submersibles with dexterous manipulators to large construction machinery.

As the domain of robotic automation is ever widened, tasks that require human sensory

perception, intelligence and dexterity in an unstructured environment are increasingly being

considered for robots. As most of the tasks involving manual labor require the use of arm(s) and

hand(s), the design of a robotic arm for a particular task usually plays a crucial role in realizing

the design objective. Long-standing interest in the application of robotic automation to labor

intensive agricultural tasks such as fruit harvesting has led to the development of agricultural

robot manipulators.

In automating agricultural tasks, the ability to reach, grasp, and/or pick biological objects can be

realized through the use of robot manipulators. As a basis for this effort, the robotic arm’s

performance capabilities (dexterity, repeatability, etc.) need to be assessed before an appropriate configuration is chosen. The availability of modern computing tools can simplify this process.

0 Comments:

Post a Comment